TOPICS

The conference will discuss Additive Manufacturing and the challenges of Industry 4.0, in addition to the digitalisation and digital transformation closely linked to it. We will analyse the most important areas and application opportunities for the use of digitalisation and Additive Manufacturing with industry leading companies.

VARINEXPO3D Tech Conference and Exhibition is an excellent forum for innovative technical professionals and those interested in the following topics.

CONFERENCE TOPICS

AUTOMOTIVE

Automotive industry is one of the key areas where 3D printing technology is starting to make a significant impact.

One of the key benefits of using 3D printing is that it enables the rapid and cost-effective production of complex, customised parts. This can be particularly useful for small-scale production or for manufacturing unique prototypes and concept models.

AEROSPACE, SPACE

Additive Manufacturing offers significant benefits for the aerospace industry. This technology enables the production of lightweight, complex parts that can reduce aircraft weight and fuel consumption. Through unique design and customisation, parts can be made more efficient and reliable.

Additive Manufacturing also offers the potential for faster prototyping and parts replacement, which can improve maintenance processes and fleet management. The use of 3D printing also opens up new opportunities for innovation in the design and development of new aircraft and for improving aviation safety.

Additive Manufacturing offers revolutionary opportunities in aerospace and space missions. It can enable astronauts to produce and repair parts in situ in space or on other planets, reducing the cost and complexity of missions.

3D printing enables the creation of custom parts that are tailored to specific problems to be solved in space. Additive Manufacturing also makes it easier to optimise the lightweight, durable and heat-resistant materials that are critical to the development of space technology.

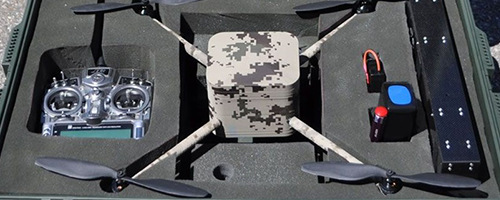

DEFENCE

Additive Manufacturing has revolutionised the military and defence sector. The technology enables precise manufacturing of customised and complex parts that can improve the performance and efficiency of weapon systems. Rapid prototyping means faster iteration and acceleration of development.

Additive Manufacturing can reduce the logistical burden of operations by manufacturing critical components and tools on-site, and can contribute to innovation in weapon systems and increase strategic adaptability.

ROBOTICS

Additive Manufacturing and robotics are closely linked to open up new dimensions in manufacturing. 3D printing is helping prototyping, tooling, reducing costs and time to market, and speeding up the product design process.

By developing more efficient tooling, taking advantage of design freedom, customising robots, speeding time to market and being user-friendly, Additive Manufacturing enables the robotics industry to take advantage of the benefits of volume manufacturing with lower initial costs and greater efficiency gains. This, together with the wide range of applications that 3D printing can bring to the robotics industry, points to a highly innovative future.

MEDICAL, HEALTHCARE

Additive Manufacturing in healthcare enables the production of customised, personalised prostheses, implants, medical devices and instruments that can improve patient treatment and recovery.

3D printing can be used to create realistic models of tissues and organs that can help surgeons and doctors plan and practice surgeries. Additive Manufacturing can speed and improve device development and facilitate research of new drugs and therapies.

Additive Manufacturing in dentistry has many advantages. 3D printing allows more accurate and customised prostheses, crowns, bridges and implants.

DESIGN, FASHION

3D printing is having a significant impact on the design and fashion industry. Additive Manufacturing allows the rapid and accurate production of unique and one-of-a-kind design elements, allowing designers to express their creativity almost without limits.

3D printed garments, accessories and footwear created using innovative materials offer new possibilities in the fashion world, allowing the creation of customised and unique styles.

Additive Manufacturing also has the potential to promote sustainable fashion by minimising waste and overproduction, while allowing designers to create only as many products as are needed.